Technology

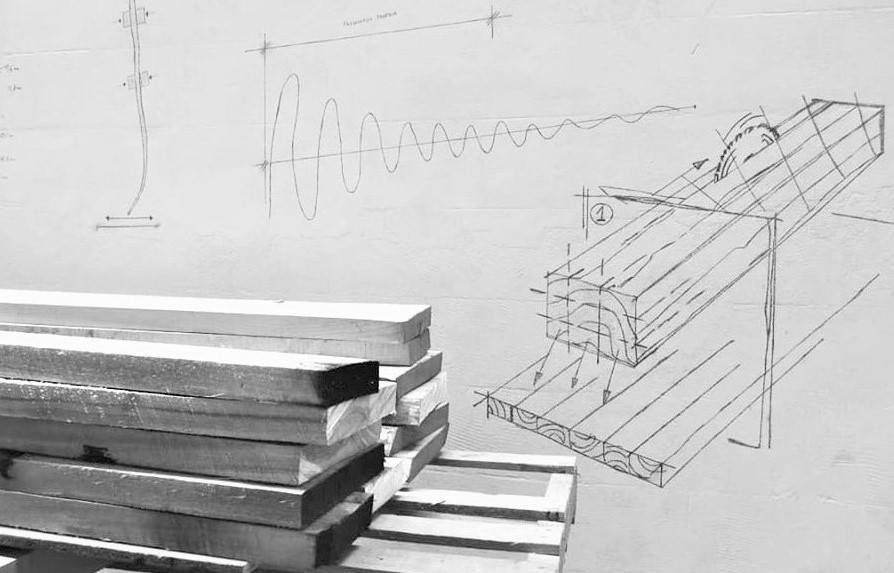

Wood is very important and decisive in the structure of high-level skis.

It occupies about 50% of the volume of the ski and GROOVES uses high quality materials for manufacturing.

The types of wood used are ash and linden.

The selection of materials is carried out beforehand at the supplier’s premises to then be treated and assembled in the laboratory to obtain an excellent product.

The sandwich construction allows you to obtain skis that offer high performance.

This technology uses materials with high mechanical characteristics.

Pre-hardened (pultruded) fiberglass laminates or high-tech hybrids are used in the manufacture of the ski, which offer the possibility of customizing the ski to the athlete by modifying the laminates and other components.

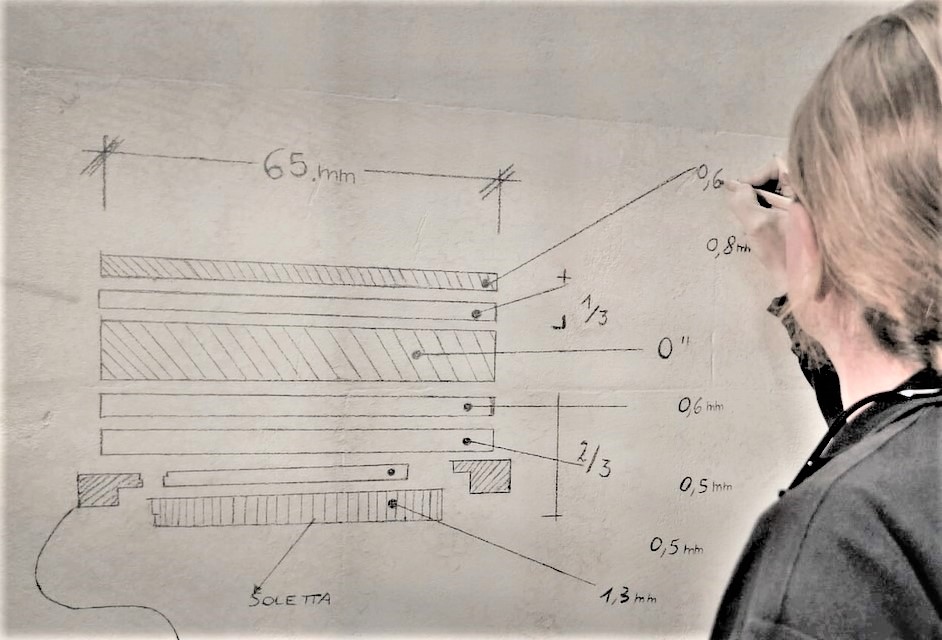

GROOVES uses the three types of thermoplastic polymers, polyethylene (PE) for the insoles, ABS for the sides and PA for the surfaces.

Thanks to its long experience, GROOVES uses PA for all surfaces, a material that is particularly resistant to impact even at low temperatures; it retains its particular elastic properties and vibration damping element, unique prerogatives not present in any other material.

GROOVES uses fiberglass laminates with bidirectionally woven glass fibers that create an anti-torsion effect in the ski. The glass fibers woven in a monodirectional way improve the structural toughness and the elastic recovery.

The best sandwich combinations are those that use both laminated fiberglass and triaxial textile materials at the same time in order to better distribute the bending loads on the external materials and the shear loads on the core.

Polyethylene is the material that has the lowest coefficient of friction in contact with the snow. The basic granule is obtained through the polymerization of ethylene worked with special reactors loaded with very high pressure and high density because they undergo a very slow stabilization and cooling cycle. Before transforming the granule, stabilizing and antistatic charges can be added to optimize the product.

GROOVES uses sintered base with ultra high molecular weight UHMW-PE (ultra high molecular weight -PE).

GROOVES manufactures skis with this type of base and proceeds with waxing treatments in thermo boxes, with IR (infrared) rays, under vacuum to obtain maximum smoothness and consequently greater speed.

The edges that are normally used are in special hardened steel with a hardness of 48 -50 Rockwell. With this hardness it is possible to resharpen them using three tools: a milling file, a semi-soft file and a diamond file.

The foils are prepared with variable angles from 90° to 86°, with incidence (tuning) from 0° to 2°, at the customer’s request.

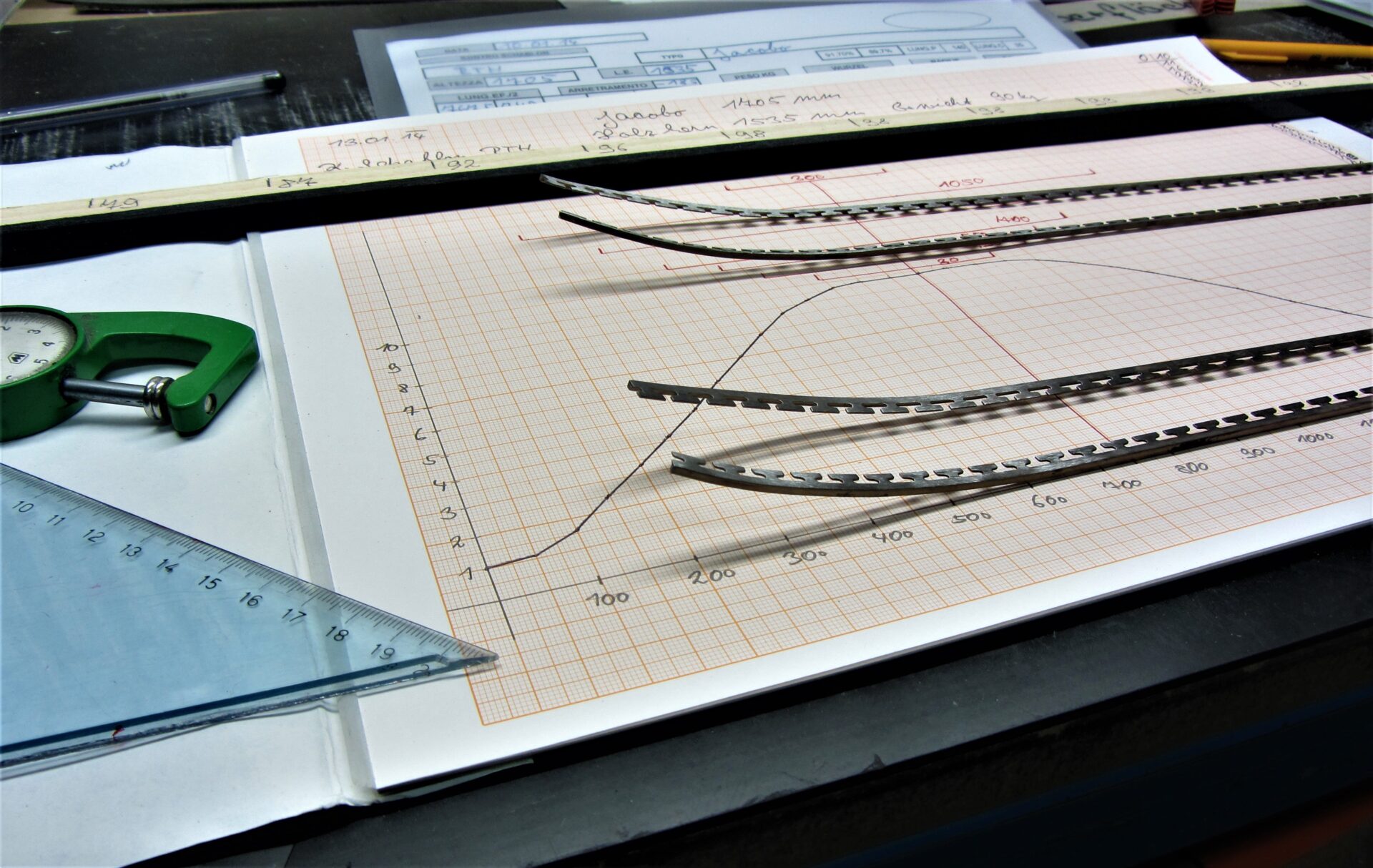

SIDECUT

The sidecut is a fundamental factor in the geometry of the ski. It balances speed, steering stability, corner entry precision, and corner exit safety.

TIP

It must have the right balance between flexion and torsion to obtain the correct ratio between stiffness and flexibility. The tip can have a twist angle of 6°-12°.

TAIL

The tail can have an angle of twist between 3° and 8°. In competitive skiing there are stiffer tails than in tourist skiing because greater precision is required in competitive skiing.

HUNDRED

The rib is the profile generated by the ski placed on a plane that creates an arc between the two contact points (LP and LC). This longitudinal bridge allows the skier’s weight to be distributed over the entire length of the ski, determining its lift.

The international standard ISO 6267 dating back to the 80s establishes a method for measuring the vibrations in the bending of the ski.

GROOVES in its many years of experience in the application of the standard, has developed a customized system with the aid of the computer.

Although the two systems are very similar, the GROOVES technology allows you to obtain more detailed results.

Through the use of the computer, GROOVES has simplified the method paying particular attention to the procedures of:

- ski locking

- ski release

- swing measurement

GROOVES with this technique is able to ensure perfect quality control by solving some problems related to vibrations.

They are a fundamental element for absorbing high frequency vibrations (for hysteresis) and at the same time for ensuring very resistant bonding. In a Grooves ski there are about 30 different parts of various sizes and thicknesses of about 0.20mm, strategically distributed throughout the ski and in its vital points. Through the elastomers and various thermoplastic materials, a blend of different shorts is created that intervene on the different frequencies of vibrations.

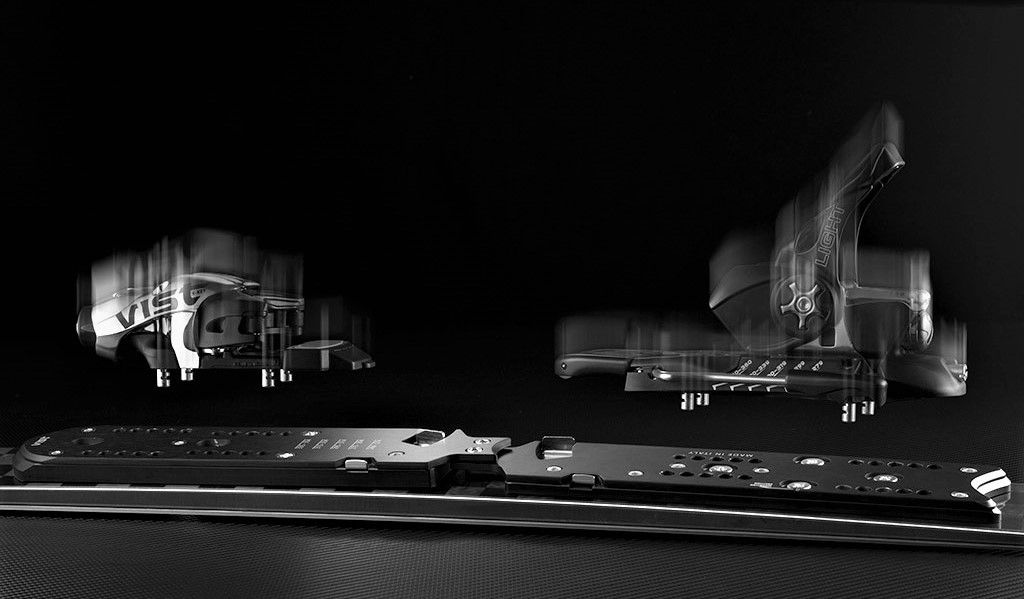

Plates and bindings play an essential role in safety on the track. GROOVES relies on the expertise of VIST, an Italian company that develops and manufactures plates and bindings 100% in Italy, with a deep knowledge of the sector for over 20 years.

VIST certifies every single attachment, checking assembly and DIN correspondence.

The construction and combination of quality materials guarantee extremely high functionality, while the assembly with careful manual work ensures maximum quality during competitive and non-competitive performance. VIST bindings are modernly designed to be able to have many customization possibilities: thanks to the PINs of the SpeedLock system and the interchangeable components, such as toe cover, lever cover, ski stopper and AFD/DIR (FREE system), combined with the vast choice of colors and shapes to choose from, you can create the most suitable variant for your taste and needs, without neglecting the color combination with the rest of the equipment.

The SpeedLock system created by VIST and mounted on GROOVES skis is the only attachment that is made with 16 steel PINS and which gives extreme stability. With this innovative system the skier will have the possibility of moving the bindings freely and without tools, positioning the centering of the boot on the ski as desired, modifying the set-up of the ski according to the type of snow.

GROOVES offers the possibility to completely customize the graphics of the ski and snowboard to make your product truly unique.