GROOVES skis represent a unique artisanal balance. They are made up of over 50 different parts, individually shaped and assembled in more than 30 successive steps. The production is entirely manual with sandwich system technology .

The core is made of selected high quality solid wood . Each strip is shaped by hand according to the desired geometry and technical characteristics. The insole has a very high molecular density with triple fiberglass inserts and ABS side panels that complete the technical equipment.

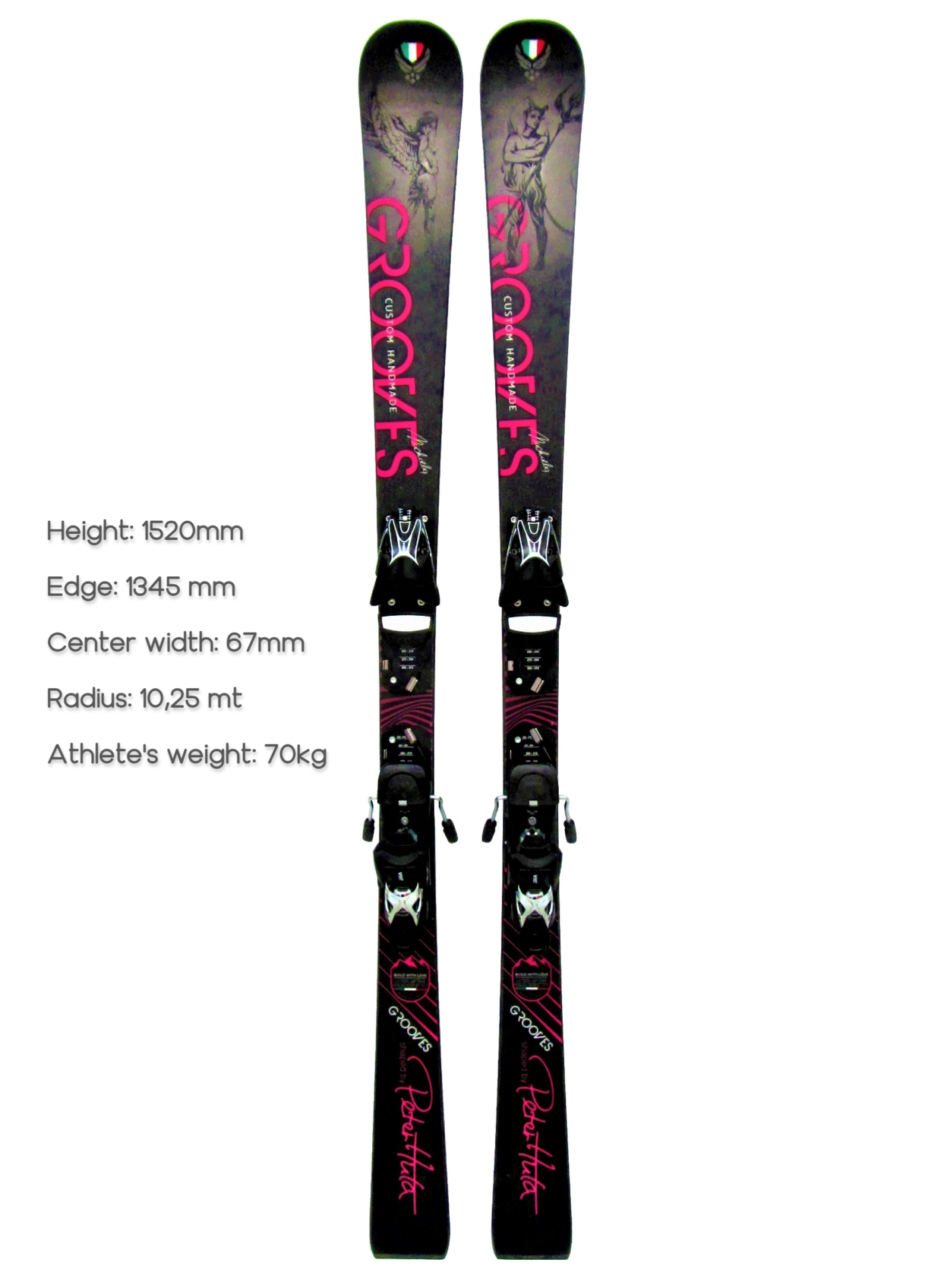

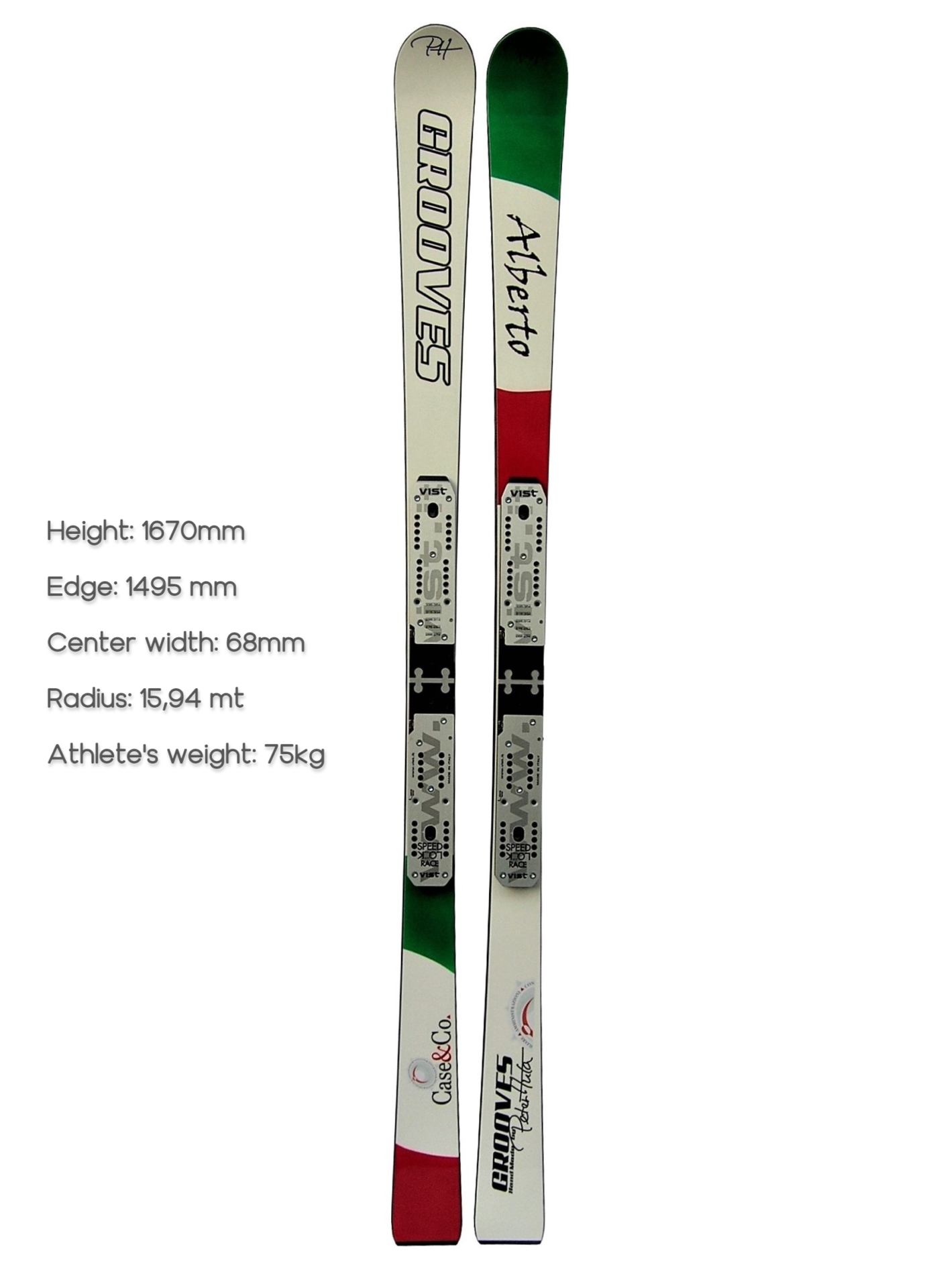

They are equipped with VIST (Italian company) plate and bindings that allow high-level performance and a personalized set-up through the SpeedLock system . This system has a hook with 16 steel PINs which, in addition to giving extreme stability, allows you to release the bindings without tools and reposition them on the most suitable size among those available on the plate.

The construction technology of GROOVES skis allows any repair intervention in case of damage and wear (edge change, base), prolonging their life.

GROOVES can modify the design by replacing the surface allowing for a new look to the ski.

After an initial period of use, the ski develops a superior performance as the structure of the materials adapts to the technical gesture, enhancing the characteristics of the skier.

The production times of GROOVES skis require a period between 3 and 9 weeks from the order.

GROOVES guarantees its products for 2 years against any manufacturing defect.